|

Lamination Machine & Varnishing Machine

| |

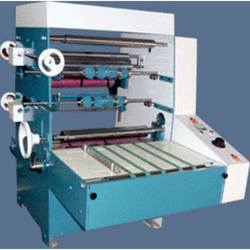

| Lamination Machine |

| |

|

Profile:

Sleek and Sturdy in Design it occupies less space and gives the Optimum.

Performance in terms of Value and Money.

Other Sizes available are 30" / 36" / 42" / 48"

Reel to Reel Attachment and Film Slitting system provided with the machines

Window Attachment can be provided with the machine against extra cost.

Salient Features

What is FIlm Lamination ?

The Process Of applying the clear polyster or PVC film on paper or board with the help of adhesive is defined as lamination.

Print Feeding

Printed/ Blank sheets to the laminating station by hand on the conveyor table. An adjustable underlap of sheets is accurately maintained at all laminating speeds. A self adjusting head allows for wide variation of thickness in the print stock.

Film & Adhesive

The solvent adhesive used for laminating is dried by passing over the heating chamber and by blown hot air. The film is bonded to the printed sheet after passing through the pressure roller made of chromed steel and ruberand are latter delivered to rewind shaft or separated immediately.

Delievery:

Delievery of finishes lamination is through the back of the laminator to rewind shaft. Sheets may be separated immediately, if desired.

Electric Controls

Machine is easy to operate & control and all electrical controls are housed in a neat panel board mounted unit easily controlled by operator. |

| Technical Specifications |

| Lamination Width ( max.) |

600 mm ( 24" ) x any length |

| Speed Maximum |

600 mts/hour 1800' / hour |

| Electrical Requirement |

750 Watts Single Phase |

| Power Load |

1.75 KW |

| Roll Width ( Film ) |

600 mm ( 24" ) Max. |

| Roll Diameter ( Film ) |

300 mm ( 12" ) Min. |

| Dimensions ( D x W x H ) |

1800 mm x 1500 x 1950 mm |

| Weight Approx. |

900 Kilograms |

|

| |

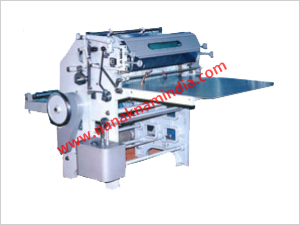

| Varnishing Machine |

| |

|

Salient Features

Designed by most qualified Technicians experienced in the field.

Fitted with Roller Bearings ensure smooth and light running of the machine.The Machine is Semi Automatic and leave impression of varnish only when paper is fed. Thus saves wastage of material , time and labour. Every part of machine is carefully tested at every stage during manufacture. It is better than many imported machines in working , structure and handling for varnishing of labels , cartoons , pictures , playing Cards, and any form for paper and cards. Conveyor belt stand with special arrangement for adjusting delivery tapes.

Trouble free Automatic Varnish up-lifting pump.

High quality of Workmanship with selected material and streamlined finish has this varnishing machine best throughout the market.Gumming is also done with this machine. |

| Technical Specifications |

| MACHINE SIZE |

18"*24" |

20"*30" |

24"*36" |

30" * 40" |

| OUTPUT ( per hour ) |

1500 to 2000 |

---- |

1400 to 1800 |

---- |

| WEIGHT |

10 Qntls |

11 Qntls |

12 Qntls |

13 Qntls |

| POWER REQUIRED |

1 H.P. |

1 H.P. |

2 H.P. |

2 H.P. |

| FLOOR AREA |

4' * 8' |

4' * 8' |

5' * 10' |

5' * 10' |

| CONVEYOR LENGTH |

21' |

21' |

21' |

21' |

| |

|

| |

| |

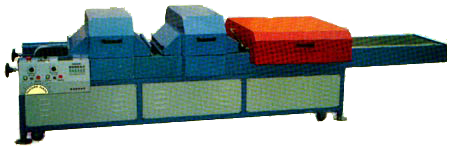

| UV Curing Machine |

| |

|

Profile:

The machine is mainly used for UV Ink & UV Varnish Curing (spot and overall) on Paper, Paper-boards, Particle boards, Wood Metal, Plastic, masking on Printed Circuit Boards.

Salient Features

Conveyorised UV Curing machines manufactured by us suitable for use with :

Varnishing Machines

Offset Printing Machines for ink curing.

Silk screen printing machines for ink curing on paper and plastic bottles.

Flexographic printing machines for ink curing on labels.

Rotogravure printing machines for ink curing. |

| Technical Specifications |

| Conveyor Width (mm) |

UV Lamps |

Length (mm) |

Width (mm) |

Height (mm) |

Power (kw) |

| 200 |

1 |

700 |

260 |

610 |

1.8 |

| 500 |

1 |

2445 |

955 |

840 |

4.8 |

| 500 |

2 |

2445 |

955 |

840 |

8.8 |

| 635 |

1 |

2445 |

1082 |

840 |

6.5 |

| 635 |

2 |

3225 |

1082 |

840 |

11.5 |

| 760 |

1 |

2445 |

1295 |

840 |

7.5 |

| 760 |

2 |

3225 |

1295 |

840 |

13.5 |

| 915 |

1 |

2445 |

1362 |

840 |

8.7 |

| 915 |

2 |

3225 |

1362 |

840 |

15.9 |

| 1015 |

1 |

2445 |

1470 |

840 |

9.5 |

| 1015 |

2 |

3225 |

1470 |

840 |

17.5 |

|

| |

| |

| |

|